Sustainability at Ratio

Read on to learn more about how we're striving to make our products, operations, and business practices more sustainable every day.

At Ratio, sustainability isn't just a buzzword. We're working to build it into everything we do, from our innovative product design to our local manufacturing approach.

Sustainability in our Products

The principles of circularity are at the heart of how we design and manufacture our products. One of our long-term sustainability goals is to eliminate waste by keeping as much of the original product material in use for as long as possible.

Every Ratio product is designed with circularity in mind, using recycled materials, minimal components, and focusing on longevity and reparability. This approach not only reduces environmental impact but ensures our customers receive products built to last.

Built for Longevity

We believe our io7 and io8 chargers represent the benchmarks of sustainable engineering in the EV charging industry. Each unit is crafted with a commitment to environmental responsibility, starting with the construction techniques used. Every component has been carefully selected to ensure minimal ecological impact throughout its lifecycle, while maintaining the highest standards of performance and durability.

We believe our io7 and io8 chargers represent the benchmarks of sustainable engineering in the EV charging industry. Each unit is crafted with a commitment to environmental responsibility, starting with the construction techniques used. Every component has been carefully selected to ensure minimal ecological impact throughout its lifecycle, while maintaining the highest standards of performance and durability.

Local Manufacturing, Lower Impact

Our manufacturing philosophy centres on keeping our supply chain as local as possible to minimise our environmental impact. By working with nearby suppliers and sister companies, we’re not only reducing transport emissions but also supporting local economies and maintaining closer control over quality and sustainability standards. This strategic approach to manufacturing and assembly allows us to build more sustainable products while strengthening the UK's green economy.

Our manufacturing philosophy centres on keeping our supply chain as local as possible to minimise our environmental impact. By working with nearby suppliers and sister companies, we’re not only reducing transport emissions but also supporting local economies and maintaining closer control over quality and sustainability standards. This strategic approach to manufacturing and assembly allows us to build more sustainable products while strengthening the UK's green economy.

Strategic local sourcing where possible reduces transport emissions and supports the UK economy whilst also reduces transport emissions.

Sustainability in our Operations

At our Redditch facility, we're putting sustainability into practice every day. From renewable energy generation to our electric vehicle fleet, we're constantly working to reduce our environmental impact across all aspects of our operations. Our commitment to sustainable practices extends beyond our products to encompass as many aspects of how we run our business as possible.

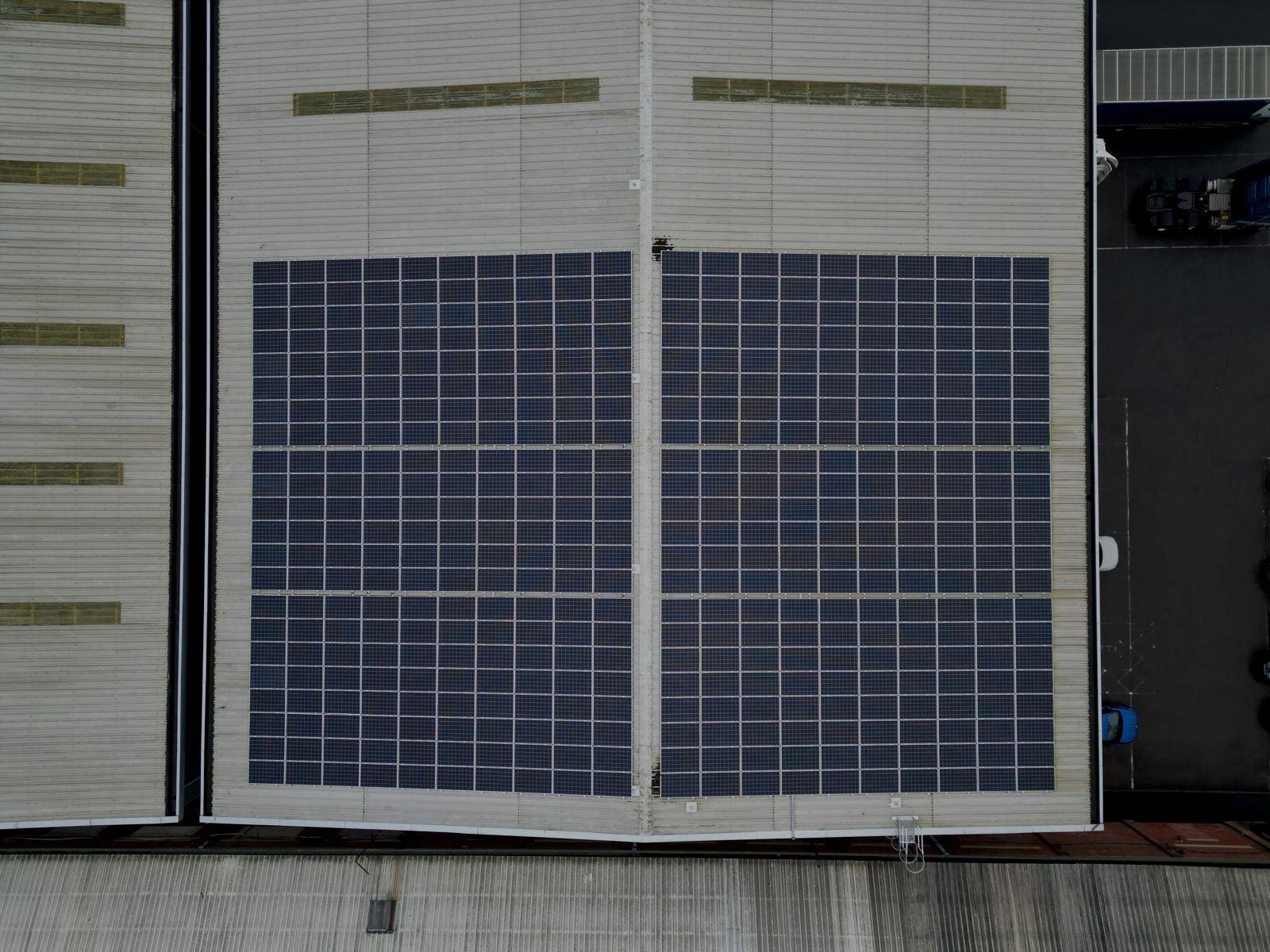

Powered by the Sun

As manufacturers of EV charging equipment, we understand the vital role renewable energy plays in the transition to sustainable transport and a net zero economy. That's why we've invested significantly in solar power generation at our own facility. This investment not only powers our manufacturing operations and charges our electric vehicle fleet, but also demonstrates our commitment to the renewable energy future we're helping to build.

As manufacturers of EV charging equipment, we understand the vital role renewable energy plays in the transition to sustainable transport and a net zero economy. That's why we've invested significantly in solar power generation at our own facility. This investment not only powers our manufacturing operations and charges our electric vehicle fleet, but also demonstrates our commitment to the renewable energy future we're helping to build.

Driving Electric

As a company dedicated to advancing electric vehicle infrastructure, we believe in leading by example. Our commitment to sustainable transport goes beyond just manufacturing charging solutions. We're actively transitioning our own fleet to electric vehicles and supporting our employees in making the switch too.

As a company dedicated to advancing electric vehicle infrastructure, we believe in leading by example. Our commitment to sustainable transport goes beyond just manufacturing charging solutions. We're actively transitioning our own fleet to electric vehicles and supporting our employees in making the switch too.

We’re Part of Something Bigger

Ratio EV Charging is a collaboration between FW Thorpe Plc and Ratio Electric B.V. Through this partnership, we benefit from and contribute to FW Thorpe Group's commitment to minimising environmental impact across all operations. As a part of the Group, we share in a range of wider sustainability initiatives beyond our own operations.

The Group has been:

“FW Thorpe Plc has a longstanding commitment to tackling global environmental challenges, principally through its core business of manufacturing energy efficient lighting equipment. The company has a genuine desire to become a more sustainable business.”

Over the last two decades, at FW Thorpe we have sought to address our carbon impact by working towards carbon neutrality for our manufacturing and distribution operations. It gives me huge pleasure that our hard work and ambitions have paid off in achieving our carbon neutral status both now and historically.

But our work doesn’t stop here. By assessing our carbon impact right across our manufacturing and value chain then setting science-based targets in line with the Paris Agreement on climate change, our goal is ultimately to reach zero carbon status well before the UK’s target for achieving net zero carbon emissions by 2050. Watch this space.

Mike Allcock

FW Thorpe Group Chairman

Looking Forward

While we're proud of our progress, we know there's always more to do. We're actively working on; expanding our renewable energy generation; further reducing packaging waste; developing even more sustainable product designs & supporting the transition to clean energy through our charging solutions

Discover our solutions